Views: 0 Author: Site Editor Publish Time: 2025-08-08 11:03:20

In industrial production processes, dust pollution not only affects the production environment and equipment lifespan but also directly threatens the health and safety of operators. As a professional provider of industrial filtration solutions, Zhuogen International Trading Co., Ltd. leverages years of industry experience and global supply chain advantages to offer high-quality dust filter cartridge products to customers across various industries. This article details the selection methods and typical application scenarios of Zhuogen's dust filter cartridges, helping you easily solve dust management challenges.

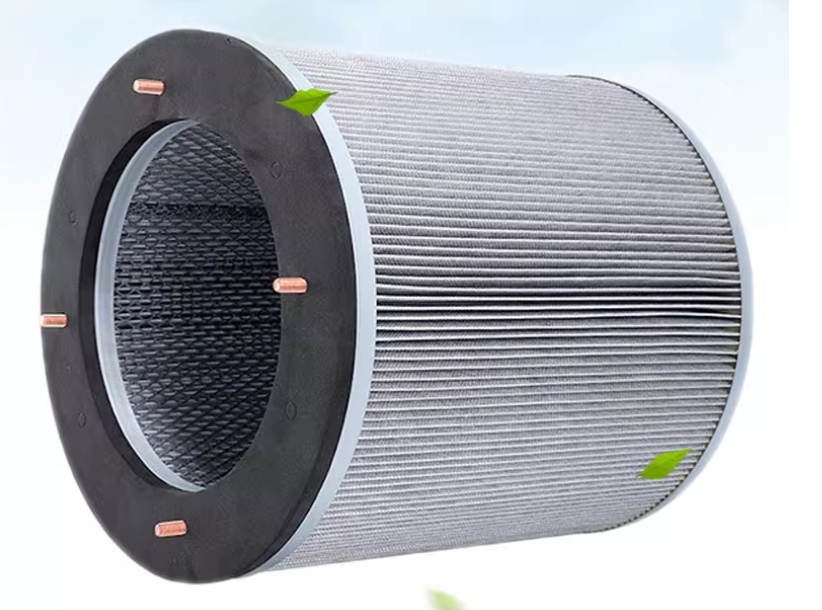

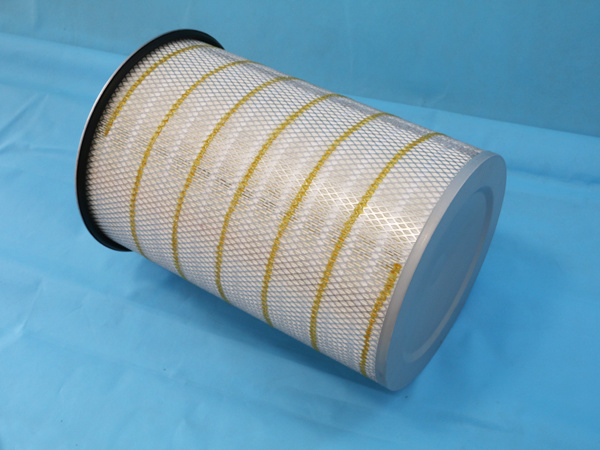

As the core component of industrial dust collection systems, Zhuogen's dust filter cartridges achieve efficient capture and separation of dust through high-precision filter materials and scientific structural design. Their core advantages are reflected in:

High-efficiency Purification: Using imported filter materials, the filtration efficiency for dust particles larger than 0.3μm can reach over 99.9%, meeting strict environmental emission standards.

Low Resistance and Energy Saving: The optimized pleated design increases filtration area, reduces system resistance, and minimizes energy loss.

Extended Service Life: High-quality materials combined with special processing techniques extend the service life of filter cartridges by more than 30% compared to ordinary products.

Customized Adaptation: Can provide fully matched customized products according to equipment models and working condition requirements.

![]()

Dust Type: Select filter cartridges of corresponding materials based on dust properties (such as abrasiveness, corrosiveness, temperature sensitivity, etc.).

Dust Concentration: For high-concentration dust, it is recommended to choose filter cartridges with high dust-holding capacity design.

Particle Diameter: Select products with appropriate filtration precision according to the particle size distribution of dust (from sub-micron to coarse particles).

Equipment Model: Provide the brand and model of dust collection equipment, and Zhuogen's technical team can quickly match the suitable filter cartridge.

Operating Temperature: Different temperature-resistant filter materials are required for normal temperature conditions (≤80℃), medium temperature conditions (80-120℃), and high temperature conditions (120-260℃).

Operating Humidity: In high-humidity environments, filter cartridges with waterproof and oil-proof treatment should be selected.

System Air Volume and Pressure: Choose filter cartridge sizes and structures that match the equipment parameters.

Food and Pharmaceutical Industry: Select food-grade filter materials that meet FDA certification.

Chemical Industry: Choose acid and alkali-resistant filter cartridges for corrosive gases.

Explosion-proof Sites: Provide anti-static treated explosion-proof filter cartridges.

Environmental Compliance: Select products with corresponding filtration efficiency according to local environmental regulations.

Including metal dust generated from welding, cutting, grinding and other processes, Zhuogen's dust filter cartridges can effectively capture iron oxide, aluminum alloy and other dust, protecting workers' health and preventing equipment wear.

In casting, polishing and other processes, for abrasive dust such as quartz sand and casting sand, Zhuogen uses special wear-resistant filter materials, significantly extending the service life of filter cartridges.

When dealing with dust from cement, lime, ore, etc., the high dust-holding capacity design of Zhuogen's filter cartridges can reduce replacement frequency and lower maintenance costs.

For scenarios with corrosive or high hygiene requirements such as chemical dust and medicinal powder, provide special filter cartridges that are resistant to chemical corrosion and meet hygiene standards.

In the processing of flour, starch, grains, food-grade filter materials are used to ensure a clean production environment and compliance with food safety standards.

Global Procurement Network: In-depth cooperation with well-known filter material suppliers in Germany, the United States, etc., to ensure product quality.

Professional Technical Support: Provide free working condition analysis and selection guidance, and customize filtration solutions.

Rapid Response Mechanism: Sufficient inventory of regular models, and 7-15 days fast delivery for special customized products.

Comprehensive After-sales Guarantee: Provide full-cycle services such as installation guidance, performance testing and usage training.