Views: 0 Author: Site Editor Publish Time: 2025-08-14 08:14:19

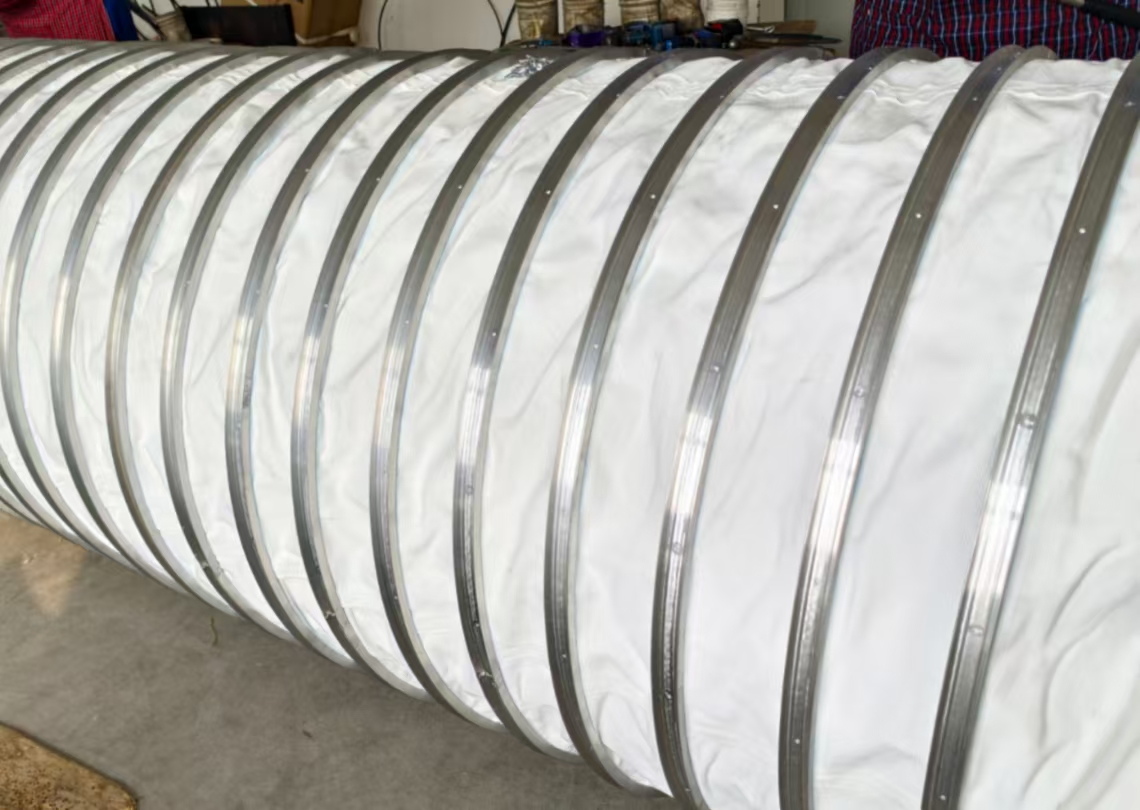

In industrial dust removal, material conveying, ventilation pipelines and other scenarios, expandable bags are the "key supporting role" for achieving flexible connection, displacement compensation, and sealed dust prevention. However, choosing the wrong model will not only lead to air and material leakage, frequent damage, but also increase equipment energy consumption and maintenance costs. This selection guide today will help you accurately lock in the suitable expandable bag from scenario adaptation, parameter interpretation to pit - avoiding skills!

The core functions of expandable bags are flexible expansion + sealed protection, but different scenarios have completely different requirements for material, temperature resistance, pressure resistance, etc. The first step must be to clarify the usage scenario:

Core Requirements: Temperature resistance (flue gas/dust temperature), wear resistance, low air permeability (to prevent dust overflow).

Common temperature ranges: Normal temperature (≤80℃), medium temperature (80 - 200℃), high temperature (200 - 600℃).

Points to note: If the dust contains sharp particles (such as metal debris), wear resistance must be enhanced; in humid environments, it is necessary to prevent condensation and mildew.

Core Requirements: Pressure resistance (positive/negative pressure in the pipeline), tear resistance, strong sealing (to prevent material leakage).

Reference pressure range: Low pressure (≤5kPa), medium pressure (5 - 20kPa), special reinforced design is required for high - pressure scenarios.

Points to note: For conveying food - grade materials (such as flour, pharmaceutical powder), food - contact grade materials should be selected, with no peculiar smell and no falling fibers.

Core Requirements: Lightweight, good flexibility, aging resistance (to adapt to indoor and outdoor temperature differences).

Temperature range: - 30℃ ~ 80℃ (conventional), and freeze - resistant materials should be selected for extreme low temperatures.

Points to note: Outdoor installation requires UV aging resistance to avoid cracking after long - term exposure to the sun.

Chemical scenarios: Need to be resistant to acid and alkali corrosion (such as sulfuric acid mist, acid - alkali steam), and priority should be given to fluorine materials or coated anti - corrosion layers.

High - temperature scenarios: For example, kiln flue gas pipelines need to withstand temperatures above 600℃, and basalt fiber or glass fiber materials can be selected.

After determining the scenario, focus on checking the following parameters, which directly determine the service life and stability of the expandable bag:

Material Type | Temperature Resistance Range | Core Advantages | Applicable Scenarios |

Polyester Canvas | - 30℃ ~ 130℃ | Wear - resistant, cost - effective, good flexibility | Normal temperature dust removal, ventilation pipelines |

Nylon Cloth | - 40℃ ~ 100℃ | High tear strength, good oil resistance | Oil - based dust, medium and low pressure conveying |

Glass Fiber Cloth | 200℃ ~ 600℃ | High temperature resistance, fire and flame retardant | High - temperature flue gas, boiler dust removal |

Basalt Fiber Cloth | - 200℃ ~ 800℃ | Ultra - high temperature resistance, acid and alkali corrosion resistance | Extreme high temperature, chemical anti - corrosion scenarios |

Fluorine Material (PTFE) | - 196℃ ~ 260℃ | Resistant to strong corrosion, non - sticky to dust | Acid - alkali chemical industry, food - grade scenarios |

Number of expansion layers: Single layer is suitable for short - distance expansion (≤500mm), and multi - layer (2 - 4 layers) is suitable for large displacement compensation (≥1000mm). More layers mean better expansion flexibility, but attention should be paid to interlayer friction loss.

Interface method: Flange connection (suitable for fixed installation, strong sealing), clamp connection (easy to disassemble and replace), zipper type (convenient for emergency maintenance), choose according to installation space and maintenance needs.

Lining/coating: For scenarios where dust is easy to stick, a PTFE coating can be added (anti - sticking); for humid scenarios, a waterproof coating can be added; for wear - resistant scenarios, a wear - resistant lining (such as rubber particle layer) can be added.

Temperature resistance: Must be 10 - 20℃ higher than the actual working temperature (to leave a safety margin). For example, if the flue gas temperature is 150℃, choose a model with temperature resistance ≥170℃.

Pressure resistance strength: For positive pressure scenarios, the "burst pressure" should be tested (≥3 times the working pressure); for negative pressure scenarios, the "negative pressure resistance value" should be tested (to avoid being sucked flat).

Expansion rate: That is, the maximum stretching/compression ratio, which needs to match the pipeline displacement (for example, if the equipment displaces 300mm during operation, choose a model with an expansion rate ≥30%).

Weight: Lightweight materials (such as polyester) are suitable for suspended installation to reduce pipeline load; heavy materials (such as basalt + metal mesh) are suitable for ground - fixed scenarios.

Low - price expandable bags may use recycled materials or low - purity fibers, resulting in a service life reduction of more than 50%. For example, for glass fiber cloth, the alkali content should be confirmed (≤0.8% is alkali - free, with better aging resistance), and high - alkali cloth (easy to embrittle) should be avoided.

Choosing high - temperature materials (such as glass fiber) for normal temperature dust removal scenarios increases the cost by 3 times but results in excessive performance; using high - pressure special bags for low - pressure conveying makes them heavy and affects expansion flexibility.

Outdoor scenarios without UV - resistant materials will crack in 1 year; using canvas without waterproof coating in humid environments will mold and block in 3 months.

Mismatched flange size with the pipeline leads to interface tearing and air leakage when forced to install; insufficient expansion length causes the bag to be pulled and damaged during equipment operation.

Choosing non - detachable fixed bags in narrow spaces requires 2 days of shutdown for replacement; in scenarios with large dust volume, not choosing easy - to - clean materials requires monthly disassembly for cleaning.

List Requirement List: Write down 5 key information: temperature, pressure, medium (dust/gas type), displacement, and installation method.

Preliminary Material Screening: Lock 2 - 3 materials from the table according to temperature and medium (for example, 150℃ dust conveying → polyester canvas/medium temperature nylon).

Parameter Verification: Confirm that pressure resistance, expansion rate, and interface size match, and priority should be given to manufacturers that provide "free sample testing".

Scenarios determine materials, parameters match working conditions, and details affect service life. Whether it is wear resistance and temperature resistance for industrial dust removal or safety and environmental protection for food conveying, after clarifying core needs and benchmarking parameters, avoiding low - price traps and excessive performance, you can choose the "most cost - effective" expandable bag.

If you are still unsure, please leave a message about your specific scenario (temperature/medium/requirements), and we will help you recommend a suitable model!