Views: 0 Author: Site Editor Publish Time: 2025-09-14 09:16:25

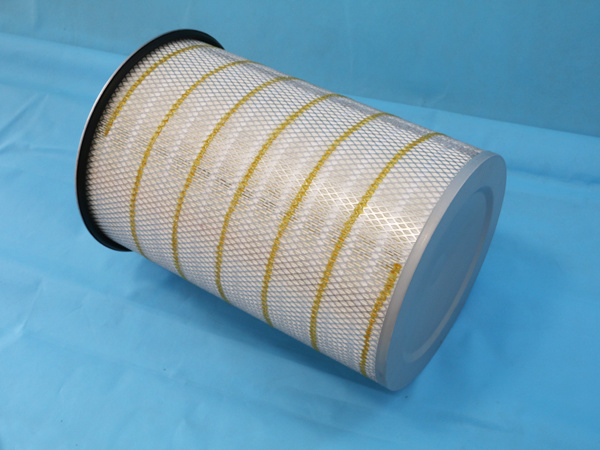

In industrial production and environmental governance, dust collection filter cartridges are key components ensuring air cleanliness and emission compliance. Their performance directly impacts dust collection system efficiency, operating costs, and service life. Rational selection, scientific application, and proper maintenance are critical to maximizing their value across industries like machinery processing, chemical production, and power metallurgy. Below is a condensed guide covering core selection criteria, scenario-specific applications, and maintenance essentials.

I. Core Selection Criteria for Dust Collection Filter Cartridges

When selecting filter cartridges, adhere to the three principles of "meeting working condition needs, performance matching, and cost control." Focus on the following six key indicators to avoid premature failure, substandard dust removal, or excessive energy consumption:1. Filter Media Material

As the core of the cartridge, filter media’s temperature resistance, corrosion resistance, and filtration precision determine its applicability. Select based on temperature, humidity, corrosive media, and dust type in the working environment:

Media Type

Temp Range (℃)

Corrosion Resistance

Filtration Precision (μm)

Typical Applications

Limitations

Polyester (PET)

-20~120

Resistant to weak acids/alkalis

1~5

Machinery (metal dust), grain, building materials (cement)

Softens above 120℃; poor against strong corrosion

Polypropylene (PP)

-30~80

Resistant to strong acids/alkalis

0.5~3

Chemical (acid-base dust), electroplating, pharmaceuticals

Ages above 80℃; low toughness at low temps

Glass Fiber

200~280

Resistant to most chemicals

0.3~2

Power (boiler dust), metallurgy, incineration

Brittle (prone to vibration damage); not fold-resistant

PTFE

-200~260

Resistant to strong corrosion/solvents

0.1~1

Pharmaceuticals (high purity), electronics (ultra-fine dust)

High cost (3-5x PET); difficult to process

Composite (e.g., PET+PTFE Coating)

-20~140

Weak acid resistance + low resistance

0.5~3

General industry (auto parts, furniture)

Poor for extreme conditions (e.g., ultra-high temp)

Key Note: For fluctuating temperatures, choose media with a maximum temperature 20℃ higher than the actual peak. For oil-containing dust (e.g., cutting fluid mist), use oil-repellent coated media (e.g., Teflon-coated PET) to prevent pore blockage.

2. Filtration Precision

Refers to the minimum dust particle size (μm) the media can capture, determined by dust characteristics and emission standards:

• Coarse dust (>10μm): 5~10μm (PET).

• Medium-fine dust (1~10μm): 1~5μm (PET/PP).

• Ultra-fine dust (<1μm): 0.1~1μm (PTFE/composite) to meet standards like China’s GB 16297 (≤10mg/m³).

3. Filtration Area

A larger area reduces dust load per unit, extending life. Calculate using:

Required Area (m²) = Airflow (m³/h) ÷ Filtration Velocity (m/min) ÷ 60

• Velocity range: 0.3~1.2 m/min (lower for fine dust, higher for coarse).

Example: A chemical workshop with 10,000 m³/h airflow and medium-fine dust (0.5 m/min velocity) needs ~333 m² (34 cartridges of 10 m² each).

4. Structural Design

Ensure compatibility with existing equipment:

• Shape: Cylindrical (150~320mm diameter, 600~1200mm length) for most systems; conical for tight spaces.

• Interface: Flange (high airflow/pressure); quick-connect (easy replacement).

• Sealing: Rubber (-20~80℃); polyurethane (-30~100℃); metal (>200℃).

5. Dust Cleaning Method

Affects blockage rate and life; select based on media:

• Pulse Jet: High-efficiency, suitable for most media (PET/PP/PTFE) – ideal for high dust concentrations.

• Vibration: For flexible media (PET) only; low-concentration dust (grain).

• Reverse Air: Gentle, for ultra-fine/adherent dust (pharmaceuticals); use with low velocity.

6. Cost & Service Life

• PTFE: High cost but 2~3x longer life – economical for harsh conditions.

• PET: Low cost but short life (1~3 months) in oil/high-temp environments; use coated PET instead.

II. Scenario-Specific Applications

1. Machinery Processing (Lathes, Mills)

• Conditions: Metal debris, cutting fluid mist, 20~40℃, ≤10mg/m³.

• Selection: Oil-repellent PET (1~3μm), cylindrical flange, pulse jet cleaning.

2. Chemical Industry (Pesticides, Dyes)

• Conditions: Chemical powder, strong acids/alkalis, 30~80℃, ≤5mg/m³.

• Selection: PP/PTFE, quick-connect interface, pulse jet. Use PTFE for solvents.

3. Power Industry (Boiler Dust)

• Conditions: High-temp smoke (150~250℃), sulfur oxides, <5μm dust, ≤5mg/m³.

• Selection: Glass fiber/PTFE, metal-sealed flange, high-pressure pulse jet.

4. Pharmaceutical Industry (Drug Powder)

• Conditions: Ultra-fine dust (<1μm), GMP compliance, 20~30℃, ≤3mg/m³.

• Selection: PTFE (0.1~1μm), fully sealed, low-pressure reverse air.

III. Usage & Maintenance Essentials

1. Pre-Installation Check

• Inspect for damage/seal cracks; confirm size/interface compatibility.

• Clean the dust collector interior to avoid media scratches.

2. In-Operation Monitoring

• Resistance: Clean at 1500~2000Pa; investigate sudden spikes (>2000Pa).

• Emission: Test regularly – replace cartridges if concentration rises.

• Parameters: Control inlet temp/humidity (dehumidify if >80% humidity).

3. Regular Maintenance

• Cleaning: Adjust intervals by dust concentration; pulse jet at 0.4~0.6MPa (0.1~0.3s/cycle).

• Replacement: 6~24 months (max 24 months); replace all at once (no old/new mix).

• Daily Care: Clean the dust hopper; inspect pulse valves; close valves during shutdown.

4. Waste Disposal

• Non-hazardous dust (grain): General industrial waste.

• Hazardous dust (heavy metals/chemicals): Licensed hazardous waste disposal.

Conclusion

Selecting, applying, and maintaining dust collection filter cartridges is a systematic process that requires integrating working conditions, emission standards, and cost-effectiveness. With stricter environmental regulations and innovative media technologies (e.g., nano-coated, high-temp composite media), filter cartridges will play a more vital role in industrial green production, supporting enterprises in achieving efficient dust removal, compliant emissions, and cost reduction.