Views: 0 Author: Site Editor Publish Time: 2025-10-09 09:04:08

In bulk solid material handling, the adaptation accuracy between unloaders and telescopic bags directly impacts unloading efficiency, dust control, and equipment service life. For powdery (e.g., cement, fly ash) or granular (e.g., ore powder, grain) materials, rational telescopic bag selection reduces dust leakage by over 80% and extends unloader core component lifespan. However, many enterprises only focus on dimensions while ignoring working conditions, leading to frequent failures. This article offers scientific selection solutions from unloader type matching, core parameter alignment, and material choice.

Clarifying unloader type is fundamental for telescopic bag selection, as different scenarios demand distinct bag structures:

Silo-bottom unloaders (fixed silo-bottom unloading): Require 3-6m vertical stroke bags, top flanged rigid connection to avoid vibration-induced misalignment and dust leakage.

Vehicle-mounted unloaders (mobile tank truck operations): Need 3-5m vertical stroke + ±15° horizontal offset, bottom conical sealing hood for automatic docking to adapt to parking deviations.

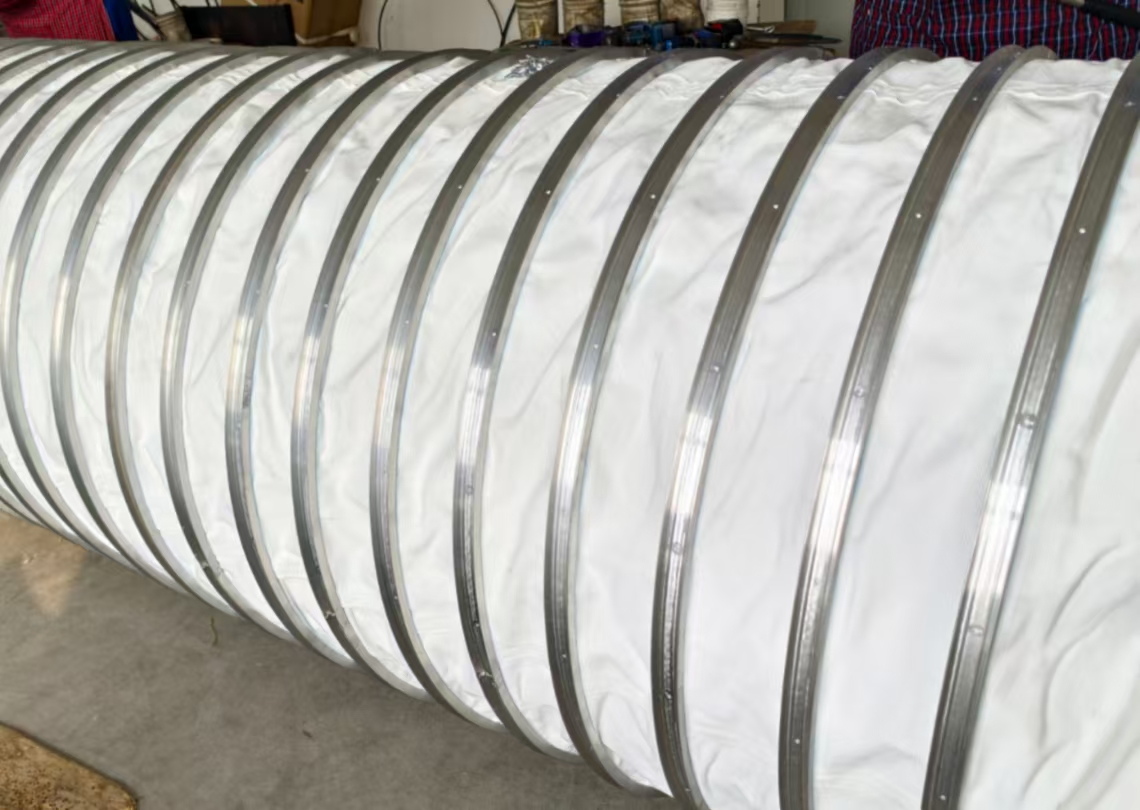

Ship-mounted unloaders (large unloading height difference): Demand 6-12m ultra-long stroke bags, outer wear-resistant canvas + reinforcing ribs to resist port wind and material impact.

Negative-pressure unloaders (dust-prone materials like flour, limestone powder): Need high-airtightness glued fabric bags with built-in support rings to prevent negative-pressure collapse and ensure smooth unloading.

Accurate core parameter matching is critical for performance:

Dimensional parameters: Inner diameter must match unloader discharge port (error ≤5mm); e.g., 400mm port needs 400mm inner diameter (over-size causes leakage, under-size risks blockage). Telescopic stroke must cover maximum unloading height difference + 10%-20% margin; e.g., 5m fixed end to tank port needs 5.5-6m stroke to avoid docking failure.

Material selection (matched to material properties): Ordinary bulk solids (≤80℃) → polyester canvas; high-temperature materials (80-200℃) → glass fiber cloth; high-wear materials → wear-resistant nylon cloth; corrosive materials → PTFE-coated fabric; viscous materials → smooth polyurethane fabric (minimizes adhesion and wear).

Common selection misunderstandings must be avoided: "Thicker fabric = better" (reduces flexibility, increases motor load); neglecting temperature (e.g., ordinary polyester for 150℃ slag powder causes thermal cracking); ignoring particle size (e.g., large-mesh canvas for fine powder leads to dust overflow). Meanwhile, daily maintenance (clean inner wall adhesion, inspect joint sealing, repair damages promptly) extends bag life to 2-3 years.

In summary, telescopic bag adaptation follows "type matching, precise parameters, material suitability," considering actual working conditions. Scientific selection boosts efficiency, controls dust, cuts maintenance costs, and supports stable bulk material handling.