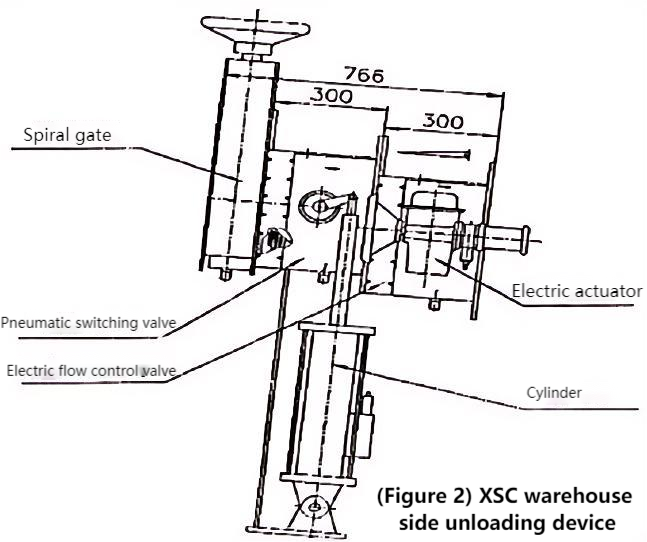

The bottom discharge device consists of a bottom spiral valve, a bottom sorting box, a pneumatic switch valve, an electric flow control valve, and a discharge chute (see Figure 1), used for discharging cement raw material powder or cement bottom. The bottom discharge device of the warehouse can automatically adjust the discharge flow rate uniformly, with a reasonable structure and simple and convenient operation and maintenance. It can be equipped with up to three discharge ports, and users can also choose the side discharge device of the warehouse (see Figure 2).

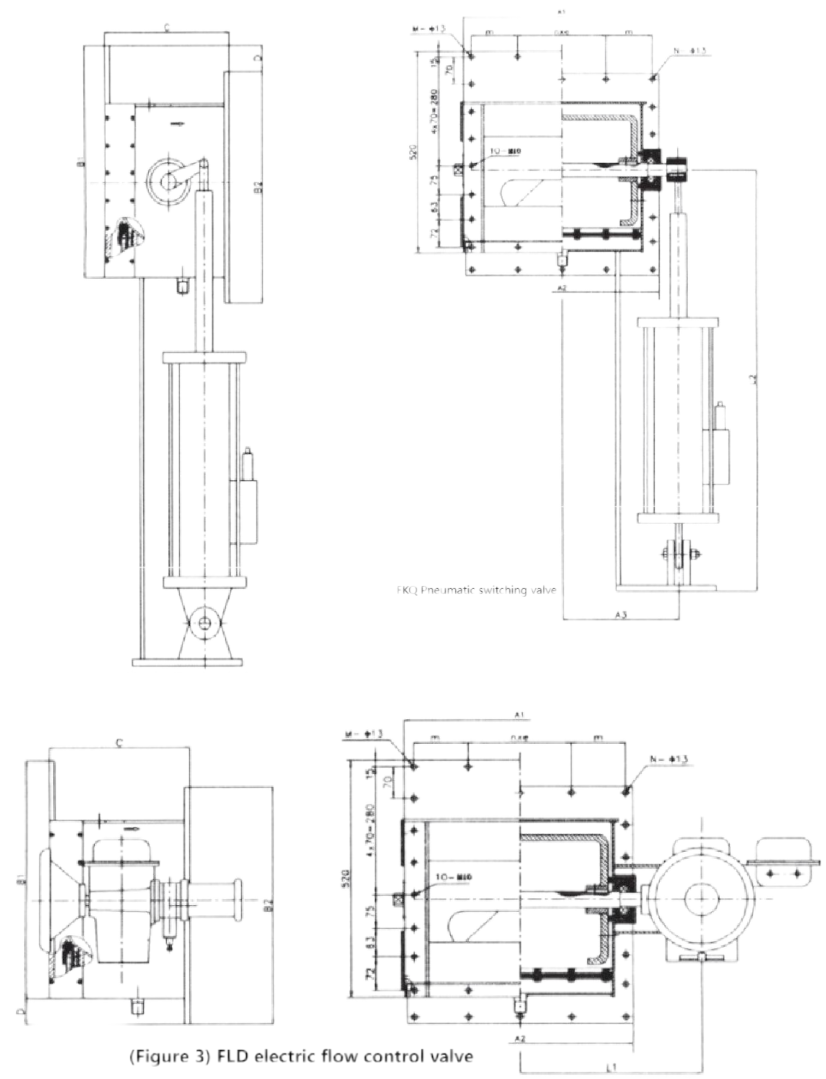

The pneumatic switch valve (see Figure 3) and electric flow control valve (see Figure 3) of our unloading device are manufactured using German technology. The valve core and housing are made of 16Mn steel, and the valve core surface is chrome plated with a thickness of 10μm to increase its wear resistance. The sealing of the valve core is made of high-quality integral felt, and the tightness of the sealing box can be adjusted externally. When replacing, it can be pulled out from both sides without disassembling the valve body. The valve core opening and housing components are made by laser cutting and machine tool processing, fully ensuring high-precision equipment assembly.