Instructions for the use of hydraulic control pipelines  Hydraulic control pipeline, also known as capillary. Mainly used for underground capillary pressure measurement in oil and gas fields, that is, temperature and pressure sensors (also known as underground permanent pressure gauges, usually nitrogen gas cylinders) are lowered into the oil and gas reservoir several kilometers deep underground along with the production string of the oil and gas well. Then, the hydraulic control pipeline (capillary)is connected from the temperature and pressure sensors to the fluorescent display on the ground, so that the underground temperature and pressure can be transmitted to the ground through the capillary, The real-time monitoring of underground temperature and pressure can be achieved by reading the instantaneous temperature and pressure at the oil and gas reservoir through the fluorescent screen of the ground display.

Hydraulic control pipeline, also known as capillary. Mainly used for underground capillary pressure measurement in oil and gas fields, that is, temperature and pressure sensors (also known as underground permanent pressure gauges, usually nitrogen gas cylinders) are lowered into the oil and gas reservoir several kilometers deep underground along with the production string of the oil and gas well. Then, the hydraulic control pipeline (capillary)is connected from the temperature and pressure sensors to the fluorescent display on the ground, so that the underground temperature and pressure can be transmitted to the ground through the capillary, The real-time monitoring of underground temperature and pressure can be achieved by reading the instantaneous temperature and pressure at the oil and gas reservoir through the fluorescent screen of the ground display.

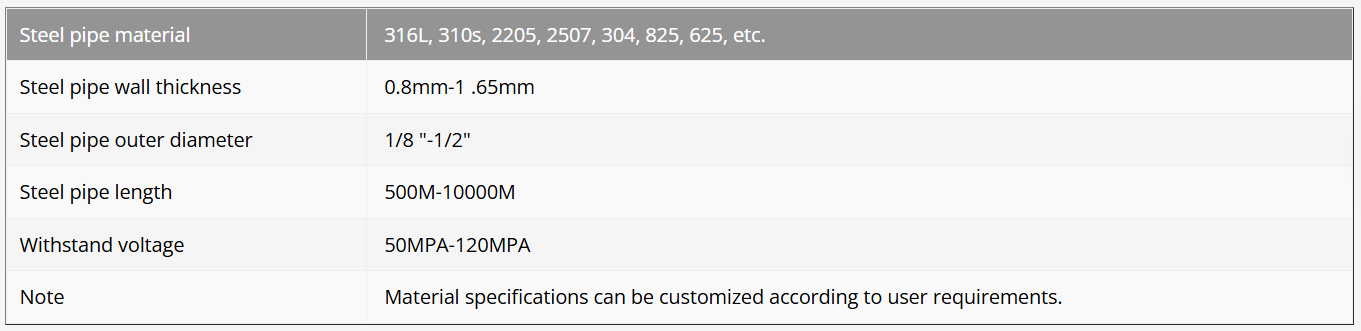

Hydraulic control pipelines are also used to inject chemicals into oil and gas wells. Connect the hydraulic control pipeline to the underground chemical inject-tion valve, and inject the detergent chemical from the ground into the oil pipe at a certain depth underground through the hydraulic control pipeline and chemical injection valve, effectively removing scale from the oil pipe and ensuring normal production of the oil and gas field. It can also be used for pressure control of surface safety valves and other surface valves, as well as various connecting pipelines for instrument control systems of large equipment in oil and gas field drilling and production. Note: Material specifications can be customized according to user requirements.