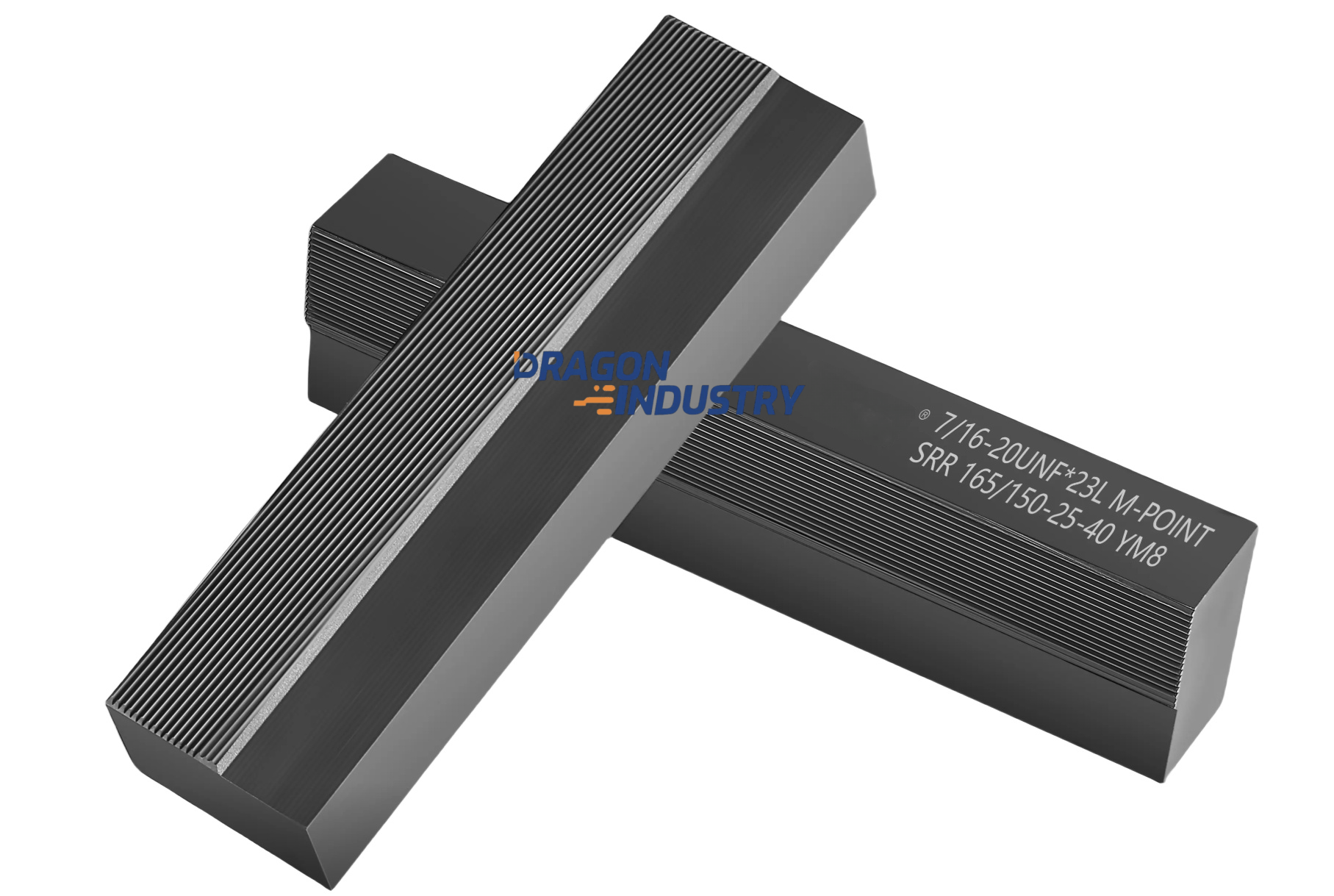

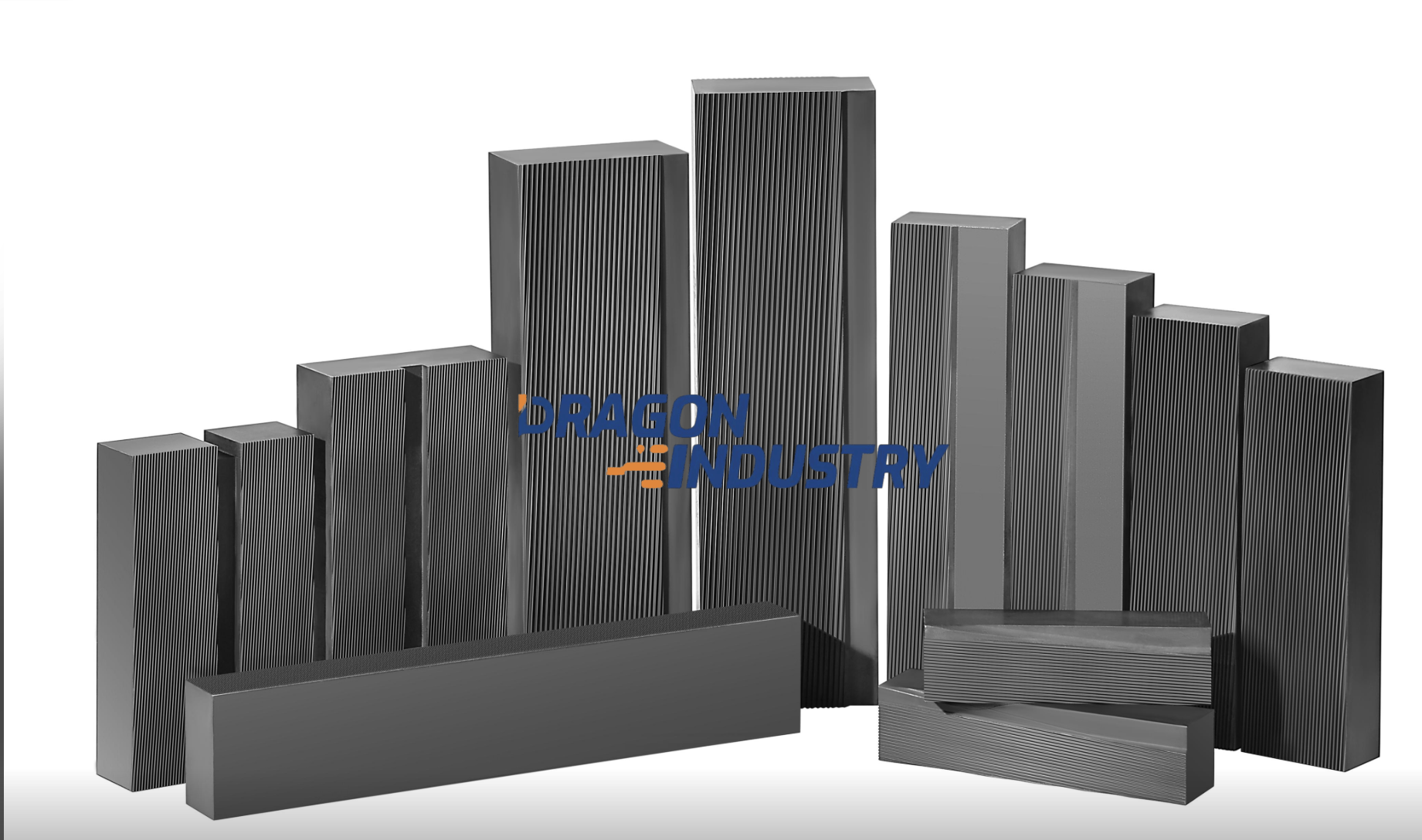

A thread rolling die is a core mold used in fastener production for cold extrusion of threads. It consists of two upper and lower plates with mirror-symmetrical thread patterns, where the lower plate is fixed and the upper plate moves reciprocally to form threads on metal blanks through plastic deformation during rubbing. Made of alloy tool steels like 9SiCr and Cr12MoV or high-speed steels, it has a hardness of HRC 58-62 and thread profile accuracy controlled within 0.01-0.02mm. Compared with cutting processes, it improves production efficiency by 30%-50%, material utilization rate exceeds 95%, and the rolled threads feature dense surface structure with 10%-20% higher tensile strength. It is widely applied in thread processing of standard parts such as bolts and nuts, as well as high-strength fasteners for automotive applications.

High-Efficiency Production: 30%–50% faster than cutting processes, ideal for mass-producing threads on fasteners like bolts and studs.

Enhanced Performance: Rolled threads feature denser surface structure with 10%–20% higher tensile strength than cut threads.

Structural Design: Composed of two mirror-image threaded plates (fixed lower plate + reciprocating upper plate) with tooth profile accuracy up to 0.01–0.02mm.

Alloy Tool Steel (e.g., 9SiCr, Cr12MoV): Hardness HRC58–62, wear-resistant and impact-resistant.

High-Speed Steel (e.g., W18Cr4V): For high-strength threads or stainless steel materials, offering superior wear resistance.

Standard Fastener Production: Thread forming for bolts, nuts, self-tapping screws, etc.

Automotive/Aerospace: Thread processing for high-strength fasteners (e.g., engine bolts).