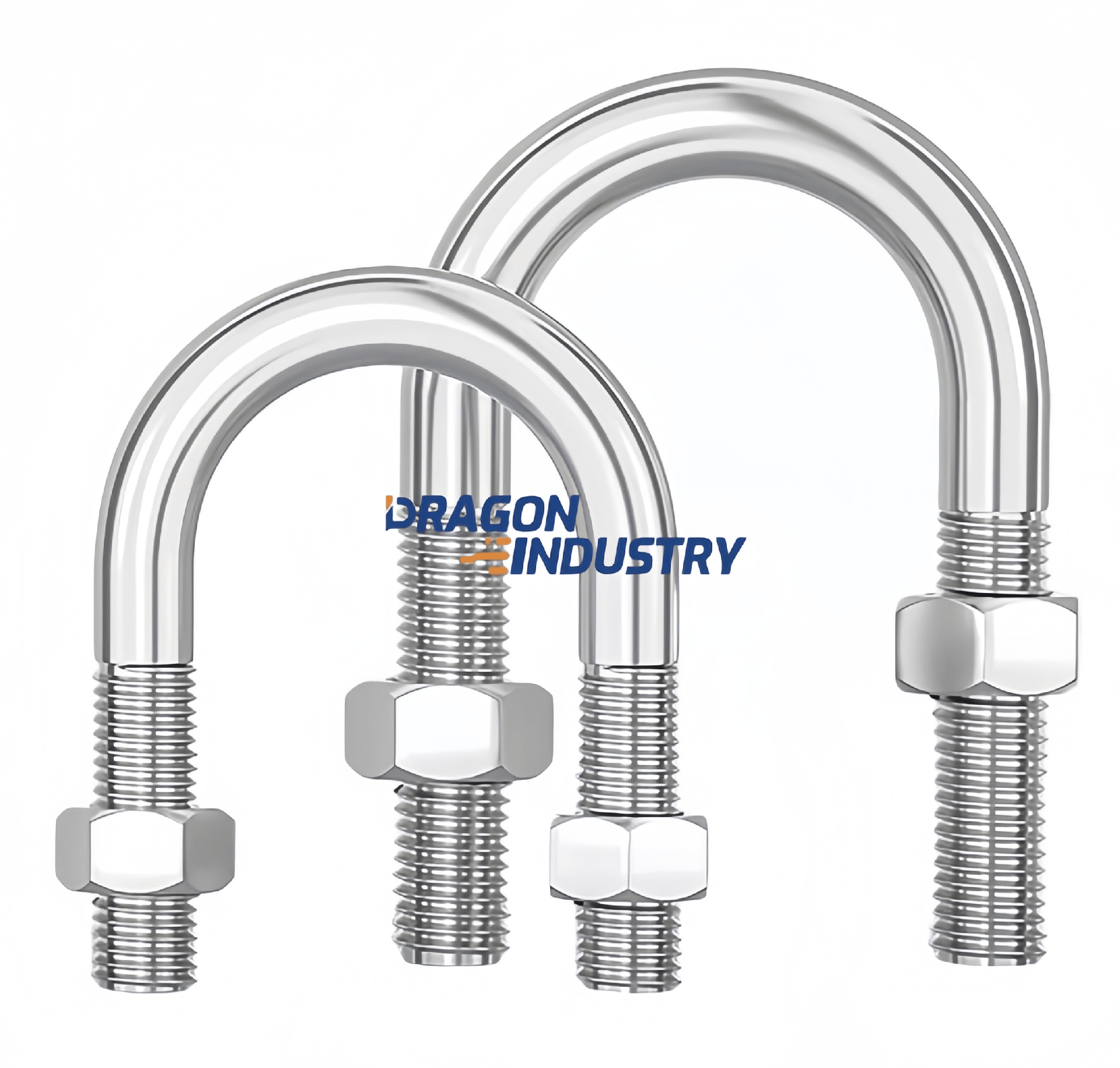

The U-shaped screw, named for its "U" shape, is formed by welding or bending two parallel screw rods with a top arc (or straight) segment. Both ends are threaded, allowing objects to be clamped and fixed by nuts.

Used for fixing cylindrical objects (e.g., pipes) or maintaining stability in vibrating environments (e.g., industrial equipment).

The U-shaped opening directly clamps the object, and after tightening the nuts at both ends, it forms an encircling force. Pre-drilling is not required, featuring high installation efficiency and suitability for temporary or permanent fixing.

Construction Engineering: Fixing formwork supports, hoisting water supply and drainage pipes, or embedding in concrete to fix steel structures.

Mechanical Industry: Supporting machine tool equipment, fixing circular pipes (e.g., steam pipes, oil pipes), or serving as connectors for equipment bases.

Power/Communication: Fixing crossarms on utility poles, cable trays, or clamping optical cables, lightning conductors, etc.

Carbon Steel (Q235, 45# Steel): Suitable for ordinary scenarios, requiring anti-rust treatments (galvanizing, painting).

Stainless Steel (304/316): Ideal for humid and corrosive environments (e.g., chemical industry, marine engineering).

Dimension: Choose the U-shaped opening width according to the object's diameter, and ensure the thread length meets the nut tightening requirement.

Load Capacity: Confirm the load requirement and select materials with corresponding strength grades (e.g., 40Cr steel for high-strength bolts).

Anti-loosening: In vibrating scenarios, use double nuts or anti-loosening washers to prevent nuts from falling off.