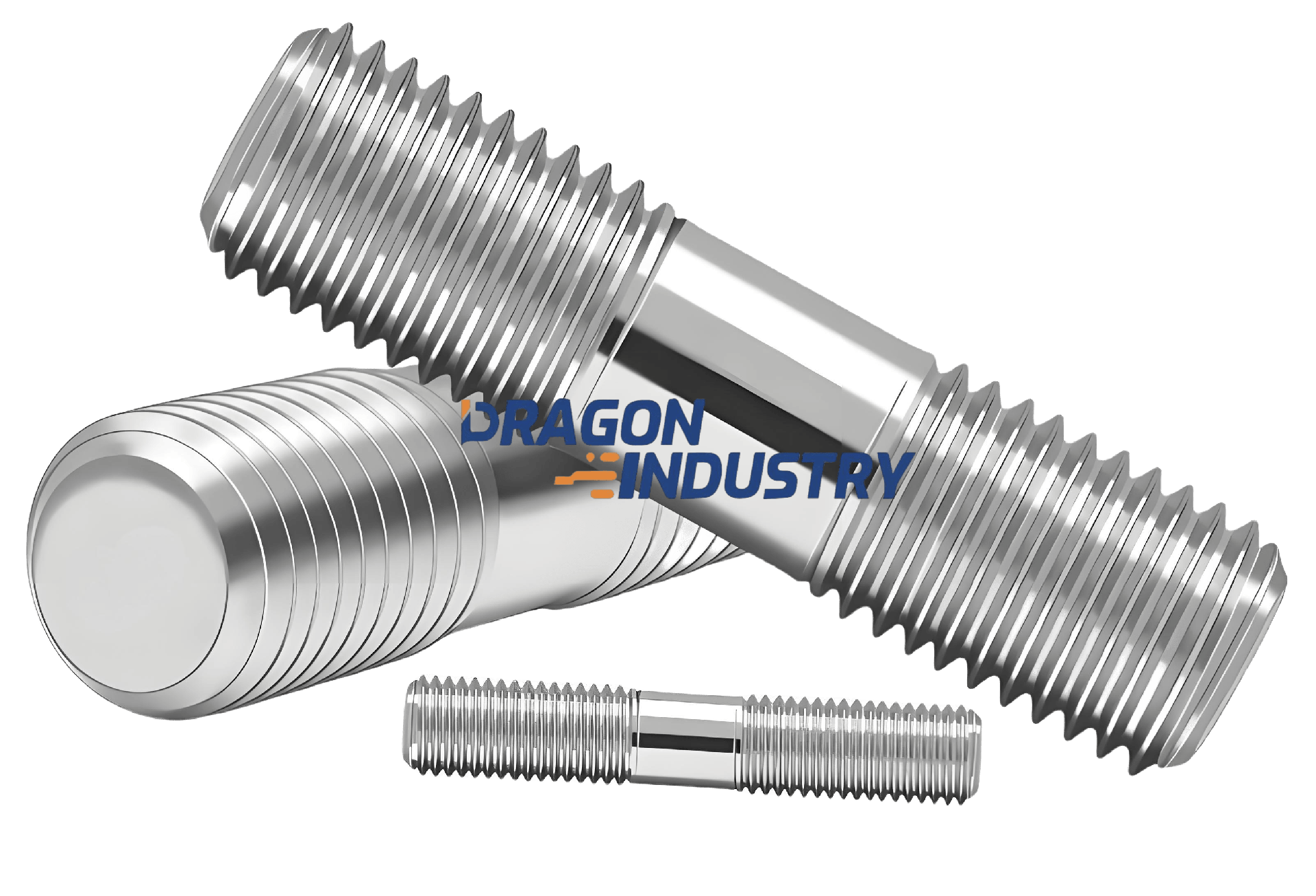

A Double-Ended Stud is a rod-shaped fastener with threads at both ends and a shank (or full threads) in the middle, featuring no head structure. It relies on nuts at both ends for connection and fixation. Its typical structure includes:

Threaded segments at both ends, which can be of equal or unequal lengths (e.g., one end for screwing into a threaded hole, the other for nut installation);

The shank diameter in the middle usually matches the nominal thread diameter to ensure overall strength.

Connection Flexibility: Requiring no head space, it can pass through through-holes or screw into blind holes, suitable for space-constrained scenarios.

Uniform Force Distribution: Symmetrically loaded at both ends, ideal for applications with high axial loads (e.g., flange connections).

Easy Disassembly: Only nuts need to be unscrewed during disassembly, while the stud remains in the fixed part for convenient reinstallation.

Mechanical Engineering:

Flange connections (e.g., pipe flanges, pressure vessels), where the stud penetrates flange holes and is clamped by nuts at both ends for sealing.

Fixing bases of motors, pumps, etc., or connecting bearing blocks to supports.

Construction/Bridges:

Embedded part connections (e.g., steel structure joints, curtain wall supports), with one end embedded in concrete and the other end connecting components.

Automotive/Aerospace:

Engine cylinder head bolts, wheel hub fixing bolts, etc., achieving high-strength connections via the double-ended structure.

Materials:

Carbon steel (Classes 4.8, 8.8): For general mechanical connections;

Alloy structural steel (Classes 10.9, 12.9): For high-strength scenarios (e.g., high-pressure pipelines);

Stainless steel (304, 316): For corrosive environments.

International Standards:

Metric: ISO 8734 (double-ended studs), GB/T 897-900 (Chinese standards);

Imperial: ASME B18.31.1 (U.S. standards).

Length Calculation:

Total length = Length of the screwed-in end (b₁) + Shank length + Length of the nut end (covering nut thickness + washer + allowance).

Screwed-in End Design:

For cast iron parts: b₁ = 1.25d (d = thread diameter);

For steel parts: b₁ = d.

Anti-loosening Measures:

Use locknuts (e.g., nylon insert locknuts) or threadlocker (e.g., Loctite) in vibrating scenarios to prevent loosening.